Quality Software — Non-conformities & corrective actions management

Manage non-conformities detected on your finished or in-process products and corrective action plans in a continuous improvement approach. Based on a continuous improvement approach, the QS-nc/ac module makes it possible to track and manage non-conformities detected on the products.

Presentation

Track and manage non-conformities detected on products

Based on a continuous improvement approach, the QS-nc/ac module allows to track and manage non-conformities detected on products :

- finished or in-process (Internal Non Quality),

- coming from suppliers (External Non Quality),

- coming from customers (Customer Service)

Create Quality action plans

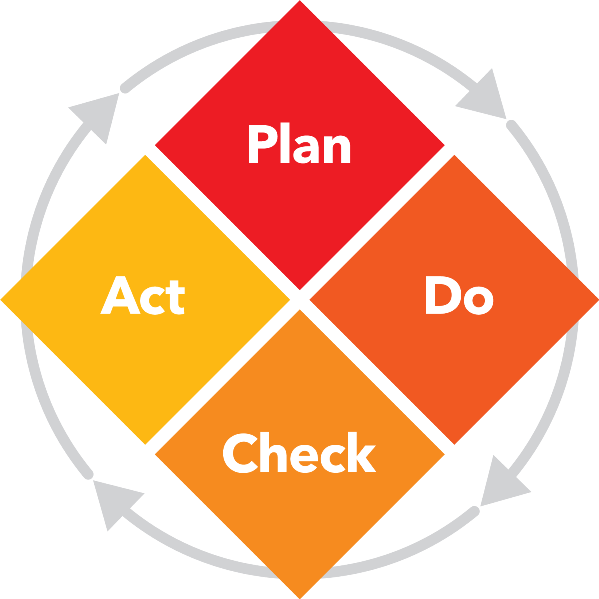

- Curative or preventive management

- Dynamic progress of actions

- Management of due date reminders

Manage your quality workflow, alerts and notifications

QUASAR includes a workflow system to define a process with steps that can be sequential, based on a value input or in a loop until a condition is met.

Work on your mobile devices

Manage your quality actions from your favorite mobile tools : tablets, PDCA…

Quality is our DNA

As a long-standing actor in quality control, we are the only company on the French market covering all quality control and management needs through our M.E.S Suite.

Integrated into your Quality system, QUASAR manages and centralizes all aspects of the industrial quality management : types, frequencies and control means, technical constraints, non-conformities management, ranking of the best suppliers, action plans, statistics…

Manage your non-conformities with QUASAR

Implementation

Pilot Project

Simulation of the software operating with your own workshop data

Easy Set Up

Only one software to install. Lightweight architecture.

Digital Continuity

We retrieve your data and connect it to your systems

Multi-sites

We coordinate the deployment of the solution on all your sites, in France and abroad

QUASAR NC / AC iN ACTION

documentation

DOWNLOAD THE BROCHURES QUASAR NC/AC

customer references

The world of QUASAR

The Digital factory close at hand

QUASAR is one of the only actors in the market to offer innovative digital solutions, enabling companies to enter the era of the Factory of the future and become smarter, more agile and within a well-defined budget.

With our modular M.E.S.* Suite, we offer manufacturers and industrialists from all sectors the opportunity to highlight the value of their data, analyse it and enhance it throughout the production chain, in integration with the information system and the teams already in place.

Even though our products can be directly linked to machines, we place people at the heart of the digital environment. We work on a daily basis to make our solutions ever easier to use, sustainable and progressive. Our key words : quality, reliability, simplicity, reactivity. Indeed, we are one of the few software publishers to be ISO 9001 certified.

*M.E.S. = Manufacturing Execution System